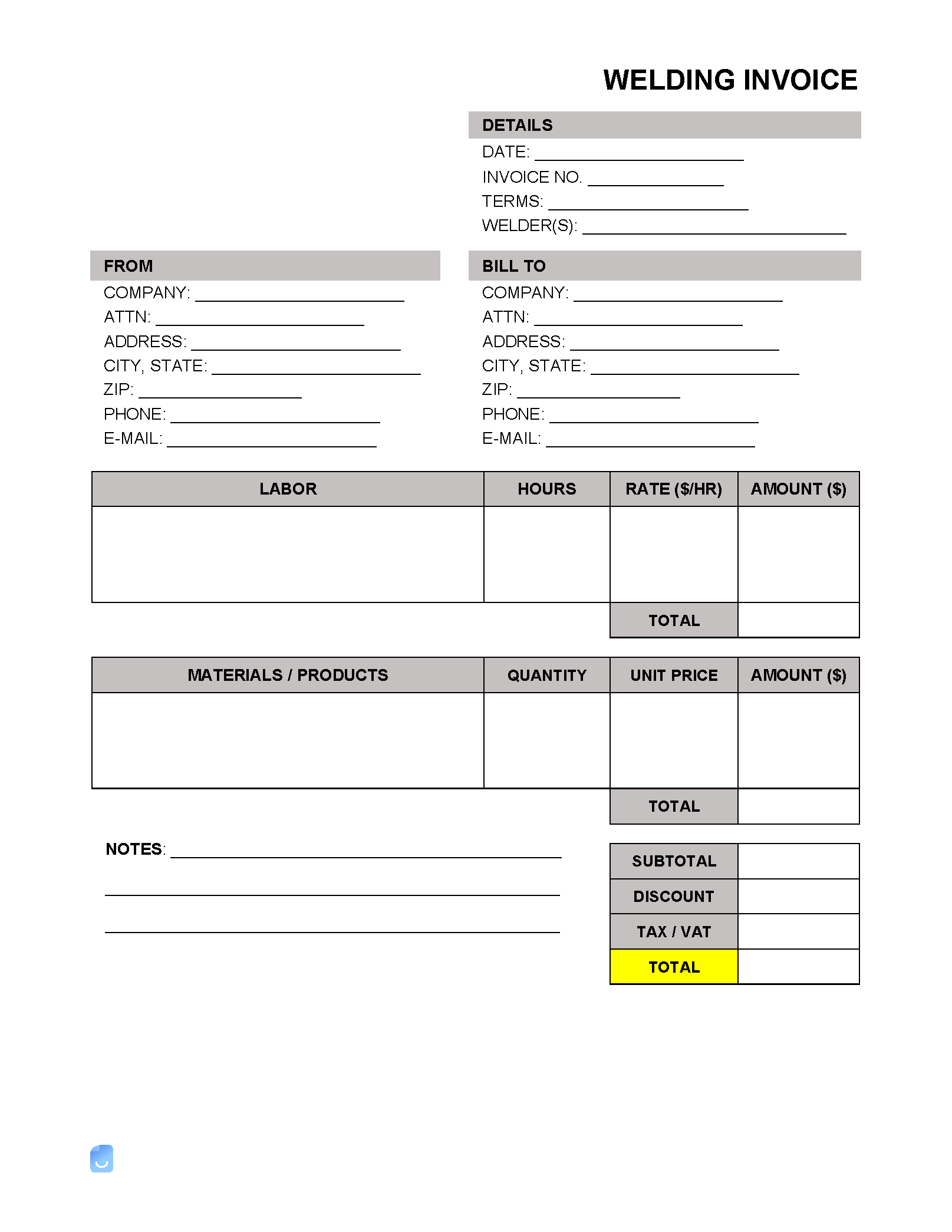

Welding Invoice Template

A welding invoice is a billing and documenting tool used by professional and part-time welders to formally request payment for both stationary and mobile welding services that are completed at the request of a client. In an invoice, welders should include a detailed breakdown of each individual cost and expense associated with the job to ensure profitability, transparency, and efficient end-of-year accounting.

What is Welding?

Welding is the process of joining two (2) or more pieces of metal. Through the use of heat, created by a concentrated beam of electricity, combustion, lasers, or friction, welders melt the joint where two pieces of metal touch, connecting the two sections.

Types of Welding

The methods in which welding is achieved can vary greatly depending on a number of factors, including the welder’s experience, the size of the job, the type of metal, and the required mobility of the welder. The most commonly used welding processes include MIG, TIG, Stick. MIG (Metal Inert Gas)

A type of arc welding that uses a wire electrode surrounded by a shielding gas, which serves to protect the molten weld pool from outside contamination. The shielding gas is typically made up of a combination of oxygen, argon, and/or helium.

TIG (Tungsten Inert Gas)

Popular for joining the metals magnesium and aluminum, TIG welding makes use of a tungsten electrode and protective gas (argon or helium) to create a weldpool, where a filler rod (typically the same metal as the metals being joined together) is then inserted to create the weld.

Stick (SMAW – Shielded Metal Arc Welding)

Electrical current is passed through a welding stick (filler rod), melting both the rod and the pieces to be joined together, creating a weld. The simplest method of welding out of the three (3).

Becoming a Welder

For those that enjoy working with their hands and appeal to the thought of a career that allows for a range of specializations, does not require a four (4) year degree, can include opportunities to travel, and can prove financially rewarding, becoming a professional welder may be the best course of action. To become a welder, the first step is to earn a high school diploma or GED. Then, hopeful candidates should look for a welding certificate or associate’s degree program in their area. The common name for a degree in welding is “Welding Technology.” After receiving the proper education, students can begin applying for open jobs near them. Entry level positions, as well as apprenticeships, should be pursued by recent graduates. For those that earned the type of comprehensive training an associates degree provides, skipping an apprenticeship and heading straight into an entry-level job is common. Upon being hired into a job and working for some time, welders may look to acquire endorsements or certifications to demonstrate their expertise to both employers and clients. The American Welding Society (AWS) is a useful resource for researching and obtaining welding endorsements and certifications. In summary, the necessary steps for becoming a professional welder are as follows:

- Earn a High School Diploma or GED

- Receive Formal Welder Training

- Apprenticeship / Entry-level job

- Certifications / Endorsements

Welder Salary & Hourly Rate ($/hr)

Salary: $48,290/yr Hourly rate: $23.21/hr (Source: United States States Bureau of Labor Statistics)