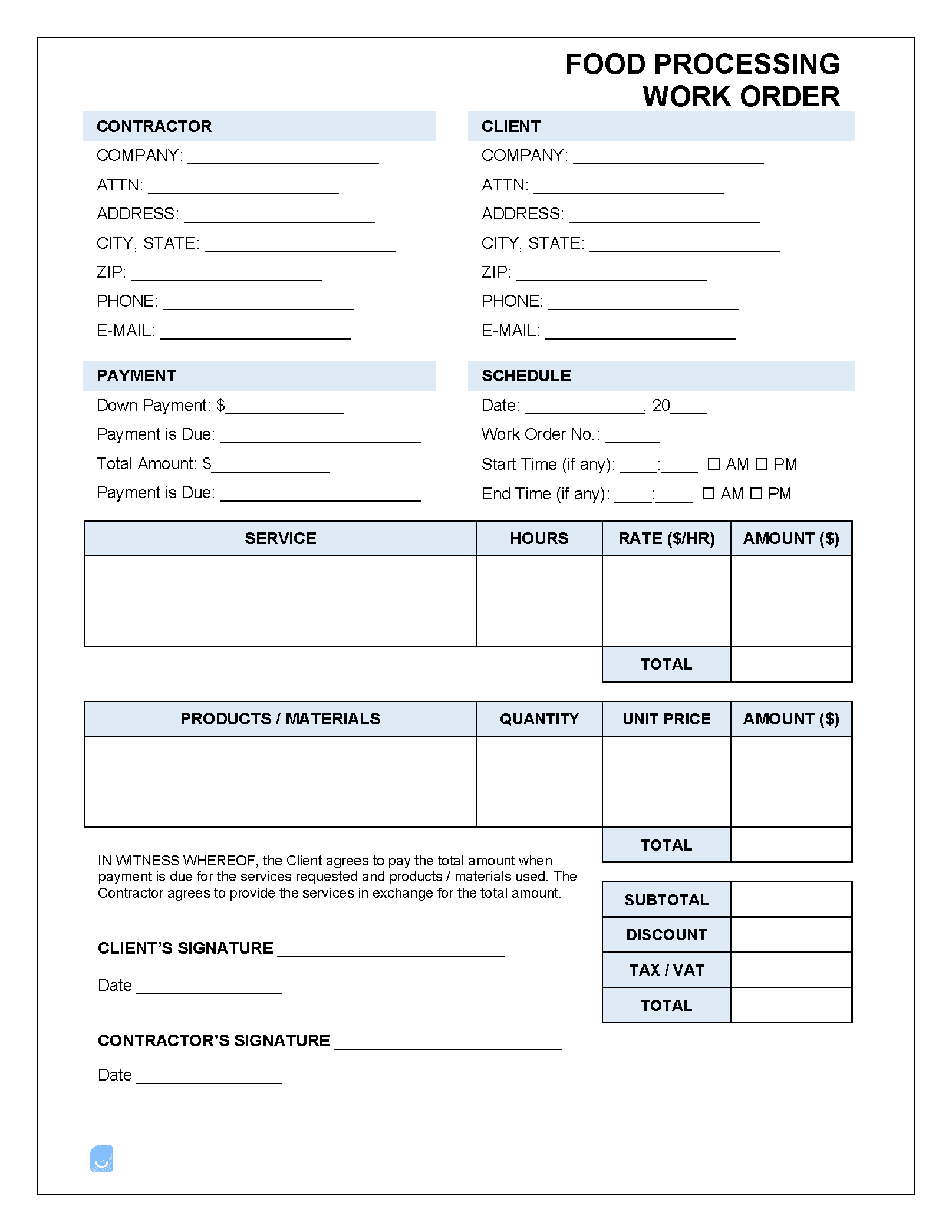

Food Processing Work Order Template

A food processing work order is used by food factories (internally) that specialize in packaging and processing foods in any of the three types which include the primary, secondary, and tertiary food processing industries.

Food Processing Work Order Details

Most companies in the food processing business are highly automated. Work orders are needed to keep teams, including operational managers and floor workers, on the same page. For example, in a meat processing plant, ground beef is normally packaged at 70% lean (minimum requirement by usda) which is instructed on a work order. However at times, ground beef is packaged at 80% and 90% lean to meet customer demands. With an effective work order, this small change can inform an entire work force and business can operate as usual. In the food processing industry, work orders serve a fundamental role in providing high quality safe food that is convenient to cook or eat. Work orders are most commonly associated with the following in the food processing industry:

- Cannery (storing food in cans)

- Fish

- Meat

- Packaging

Types of Food Processing

- Primary – The process of taking raw goods such as meat, fish and wheat and preparing it for packaging. The most important phase of food processing as health hazards are dealt with during this process.

- Secondary – Uses foods and ingredients after the primary process to create food that is ready to be cooked by consumers.

- Tertiary – Prepared foods that are ready to eat (such as frozen meals and cold cut meat). Perhaps the most unhealthy of all the processing methods.