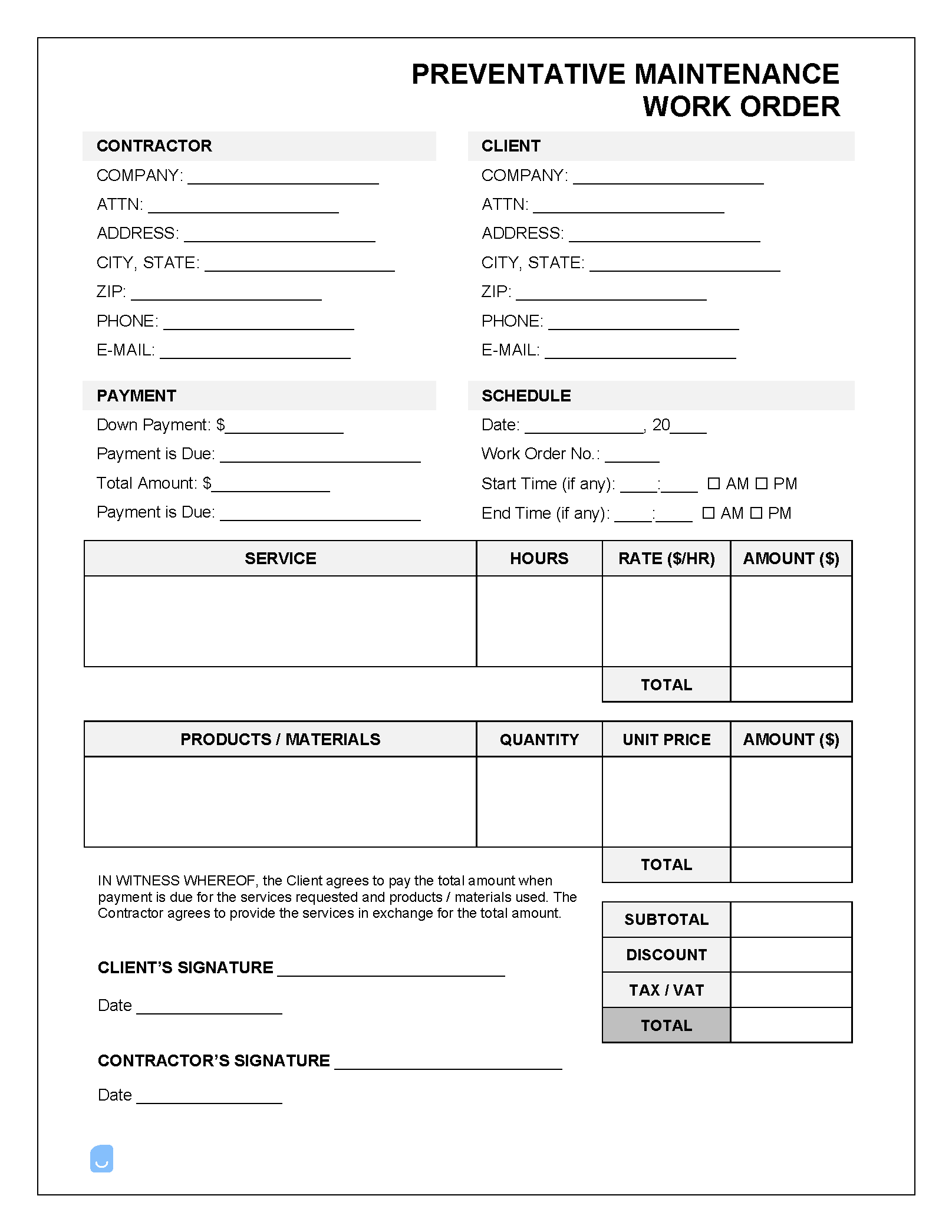

Preventive Maintenance Work Order Template

A preventative maintenance work order is a form that allows customers to place a formal request to have routine work be performed on powered equipment, engines, and other mechanical systems. Having work be performed in a scheduled matter is done to reduce the chances of the system failing prematurely. This permits systems to be operational for significantly longer periods of time than they otherwise would, saving people and businesses money in the long run.

Using a Preventative Maintenance Work Order

To effectively use a work order for scheduling (and charging) ongoing maintenance for a client, the company will need to have the following in place:

- Maintenance schedules for a wide variety of equipment – There is a good chance this is provided by the manufacturer of the product, but if not, in-house schedules will need to be drafted. Setting a frequency for maintenance repairs is essential; mark tasks as either weekly, monthly, bi-yearly, yearly, etc.

- The rates in place for maintaining equipment – In order to provide the client with a quick estimate, the rates for various jobs (labor & parts / materials) should be able to be referenced quickly.

For customers looking for one-time preventative maintenance to be performed on their equipment, using a schedule isn’t necessary. In these situations, the person completing the form should only fill-out fields that only apply to the single request. However, once work is complete, keeping a record of the repair is highly recommended to ensure future owners/techs understand the equipment’s repair history.